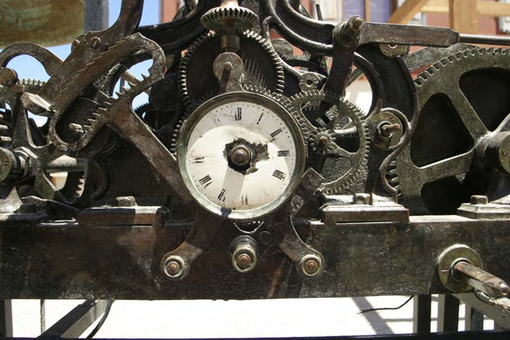

This is a picture of Ned Ludd’s prototype yokel-powered Encabulating Engine. It wasn’t until over 150 years later that engineers at General Electric managed to successfully add a turbo function, paving the way for fully miniaturized turboencabulation, the internet and eventually, Pinterest.

I’m tired and feeling sassy.

As I said at the very beginning, wire wheels are great. Other than bashing them into things, which will ruin most any wheel, wire wheels and their partners in arms the splined hub, are very easy to maintain.

With your lead hammer or spinner removal tool of choice, loosen the four wheel spinners. Safely jack up your car, set it onto jack stands because we are not idiots, and then remove the spinner and pull the wheel off of the hub. Don’t hurt yourself.

Clean the old, dead grease off. Clean it really well. There are planet-friendly degreasers that will do the job in a more planet-friendly way. I have a British car shop, so I usually have a ready supply of foul, manky, dead gasoline that I have drained from customers’ tanks. It works great. (I am NOT recommending you use gasoline. That would be bad, probably.) So, yeah, clean the old grease off of the hub and also from the inside of the wheel with whatever grease removal ritual you prefer. Use gloves if you care about your hands.

Now that everything is clean and dry, give them an inspection. Compare the splines to that unworn section on the inside of the wheel, just like I talked about. It takes 10 seconds and gives you bragging rights over your bolt-on-wheeled friends. They don’t know how to inspect splines, do they? No, sir! But you do!

Splines all good? Yay! Grab about a handful of moly-graph wheel bearing grease. If you want to dive into the forums and argue the merits of different lubricant products for use on splines, you have fun doing that. I use moly-graph because I have a tub of it on my shelf of grease-like products. It doesn’t matter. Its SOME kind of GREASE! About as much as you can grab with your fingers, not so much that you are filling your hands. (Its not mayonnaise or cake frosting. Get a full handful of that.) With a swish! and a flick!, smear that stuff on the splines of the hub. Smear it right around so its about the same amount all the way around. Don’t fill them up, that three-finger scoop will be plenty. Smear a little bit on the threads where the spinner goes.

Now, take a slightly smaller scoop and smear it on the inside of the wheel splines, smear it right around and then add a teeny bit onto the tapered face where it will meet on the hub seat. It doesn’t need much, just some. Slide the wheel back onto the hub. Smear a little bit on the outer taper of the wheel hub. Don’t go nuts, just a little bit to keep the spinner from binding or galling. Too much will just fling around and get all over your spokes. Bonk your spinner back on.

That’s it! Go around the other three corners and do it three more times. Safely lower your car back onto the ground, give the spinners another whack for extra safety and because its fun and know that you are doing it right!

Plan B, or No! my splines are scary and pointy-bad!:

I am really sorry, that truly sucks.

The worst part of my job is having to give a new customer the “wire wheel talk”. They just bought a car and want to have me check it out. I do not know why they did not have me check it out BEFORE they bought it, but that’s what they do. I casually mention as I give it the initial walk-around, “…and the wheel splines are all good?”

“Yup! Checked ‘em myself!” as he proudly runs his fingers around the spokes, plucking at them like Harpo Marx during the interlude.

“Oh, dear” says my brain. “Let’s get it up in the air and have a look-see” as I loosen the spinners with what used to be a lead hammer. More of a cudgel these days.

Sometimes I hear the slickery-snappery noise of fresh grease and the wheel doesn’t rattle when the spinner comes off. Other times I can’t get the wheel off because rust takes up more room than the parent steel and we know things are going to be bad. (Yes, I have had to use a plasma cutter to remove wire wheels.) Usually, its somewhere in the middle and I have to give a lesson on how to care for the fairly beat-up, but-OK-as-long-as-you-take-care-of-them-and-don’t-race-teenagers-around-Deadman’s-Curve splines that they got lucky to have.

And then there are those who get “the talk”, which is basically, “Sorry Sir or Madam, but your spiffy new sports car is sort of a death trap and you really need to crumple up upwards of $2,000 and throw it at your car. If you don’t, the wheels might come off.” Then we go on about the care and feeding of splines and how it hasn’t been done on this car since Reagan was in office. If we are lucky, the spare has never been used. More likely, the spare wheel in the trunk has already been spun and the good spare wheel is now on the worst hub, rapidly being chewed to death.

But I digress.

The only answer to bad splines is replacement. All of them. In the worst cases, that's four new hubs, one for each corner, two front bearing kits, I will probably have to turn the rotors so they will run true on the new hubs, time to set up bearing clearances. Add at least four, maybe five new wheels, maybe new tires. Honestly? Five new tires. No one wants to mess around with the old tires, even supposing the date code is less than ten years ago. Mount & balance five tires. The good news is that new wheels are set up with safety beads, so we don’t need to deal with tubes any longer.

Add in the “Gee, Honey, you’re doing all this. Its not that much more, just get the chrome ones.”

In for a penny, in for a pound, there is often a brake job involved. At that point, the difference is merely the additional cost of the brake parts, as I already have to touch them all to do the hubs anyway.

Sure, I like selling parts as much as the next guy. But its never fun to dump a huge bill on a customer with a new toy that is still going to leave with the same number of wheels as he came in with. New tires are always nice, but that isn’t what he/she rolled in here for. They wanted me to give a big thumbs-up and say, ”Cool car! Verra nice! Off you go, now!"

So, that’s why, though I don’t like to do the “The talk”, sometime I have to.

If you got this far, even more good news! Bonus Points! I bet you will take extra-good care of your wire wheels from now on!